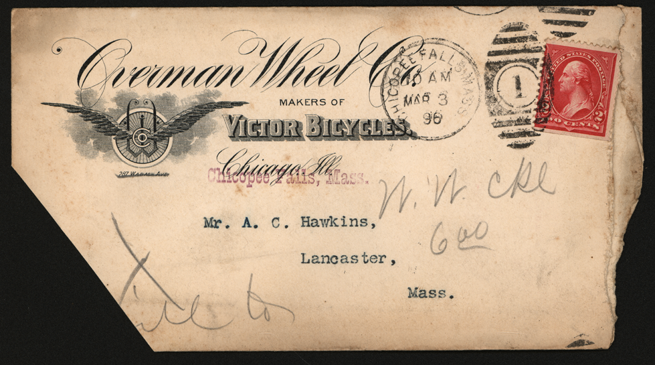

As did many bicycle makers, The Overman Wheel Company made the transition to automobiles. This advertising cover predates the Victor Steam Car.

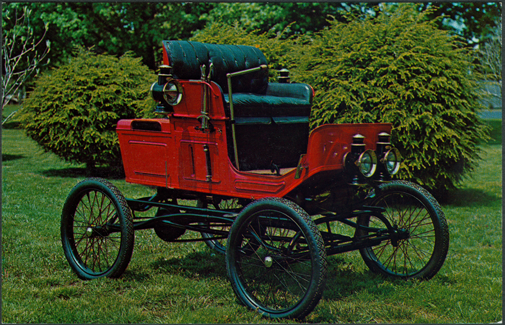

This 1901 Victor Steam Carriage Runabout is from the Ray Lindsey collection. The postcard was produced by the Long Island Auto Museum.

The Overman Wheel Co. were manufacturers of Victor bicycles and began development work on autos in 1896 when H. A. Knox was hired to design a gasoline engine. This was never put on the market and Knox left, later to manufacture the Knox and Atlas cars.

A steam car, the Victor, appeared in 1899. It was typical of the many New England steamers of the period, with 4 hp vertical 2-cylinder engine and single chain drive. In 1900 the Victor bicycle business was sold to the Stevens Arms & Tool Co., and for a few months Overman leased the top floor of the building to assemble Victor cars.

In January 1901 a new company was formed, and they took over space in a factory at Chicopee, where Victor steamers continued to be built. In 1902, A. L. Riker joined the firm, and they became associated with Locomobile.

The first Locomobile gasoline cars were developed at Chicopee as well as new Overman gasoline cars and the steamer. By 1904 the firm was wholly absorbed by Locomobile. Meanwhile the Chicopee Falls plant was used for the manufacture of Stevens-Duryea cars.[1]

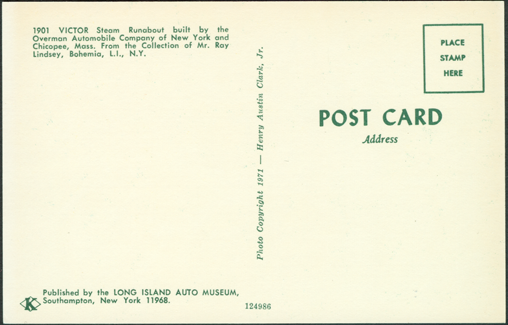

The Overman Automobile Company produced this catalogue in November 1901. Photocopy. John A. Conde Collection.

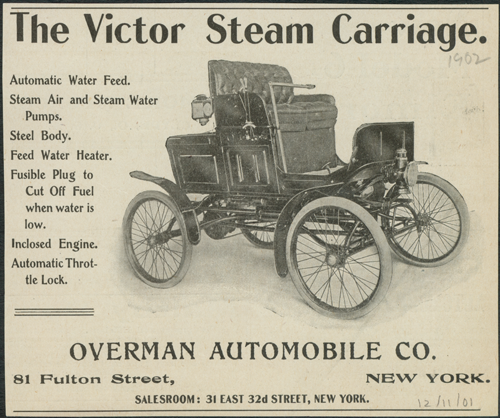

This advertisement appeared on December 11, 1901. The magazine and page are unknown.

This advertisement appeared in 1902, perhaps in the same magazine as the identical advertisement above.

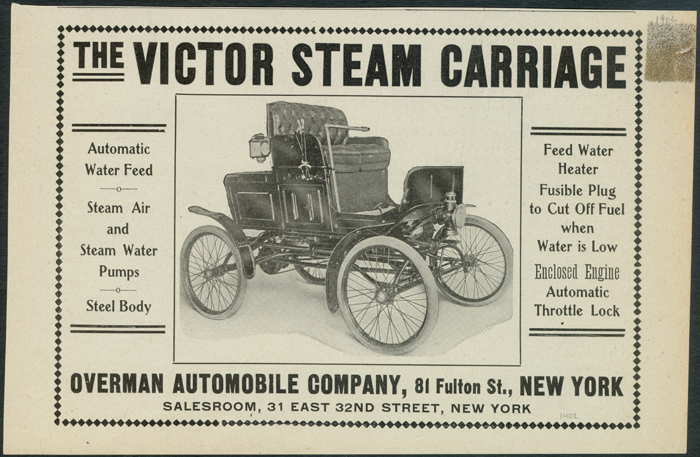

This advertisement appeared on an unknown date in Automobile Topics magazine, sometime in 1902.

This advertisement appeared on an unknown date in Motor World magazine, sometime in 1902.

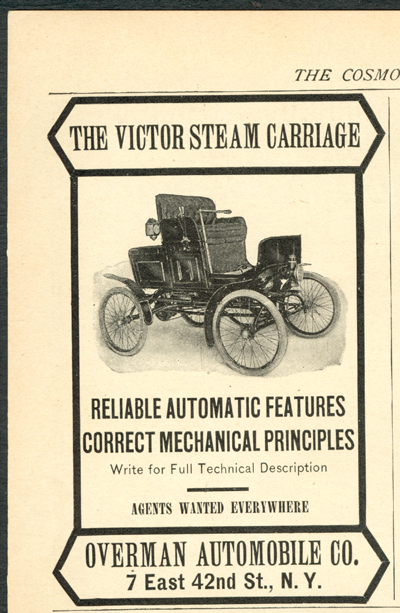

This advertisement appeared in the May 1902 issue of Cosmopolitan Magazine. The Overman Automobile Company is listed at 7 East 42nd Street, New York, NY. This was the Company's sales office. The image in this advertisement appears to be identical to the Scientific American image below.

This advertisement appeared in the June 1902 issue of Cosmopolitan Magazine.

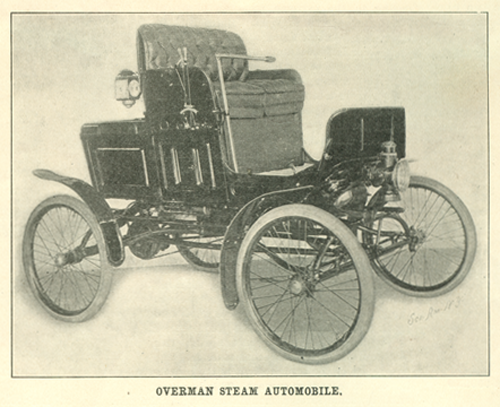

The Overman Automobile Company was featured in an article about steam vehicles in the March 1, 1902 Scientific American, p. 139. These articles were actually paid advertising in the form of news.

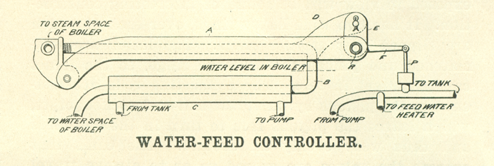

The Victor's Water-Feed Controller was featured in the March 1, 1902 Scientific American, p. 139.

In April 1902, The Overman Automobile Company announced its new price list for Vicstor Steam Carraiges on p. 27 of the Cycle and Automobile Trade Journal. Photocopy. John A. Conde Collection.

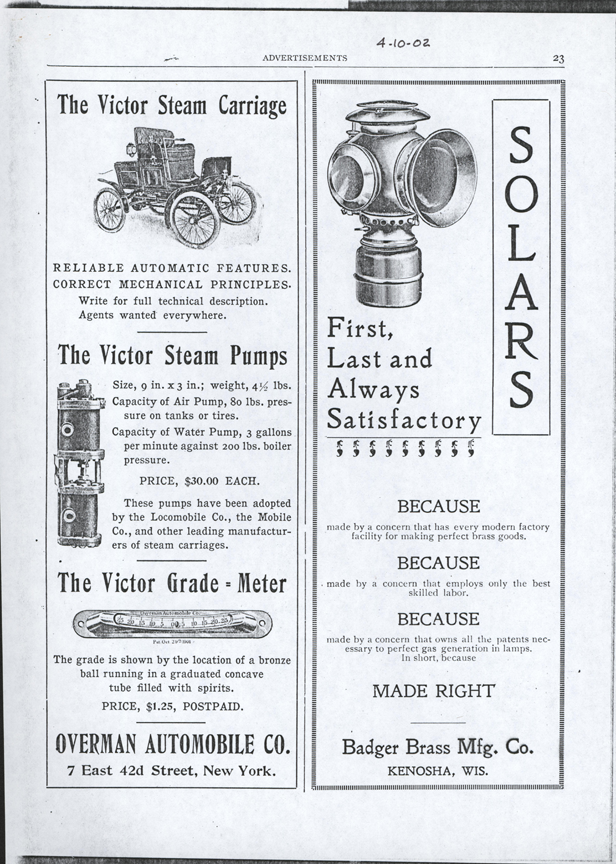

The Overman Automobile Company offered a gradiometer in this April 10, 1902 advertisement from an unknown magazine. Photocopy. John A. Conde Collection.

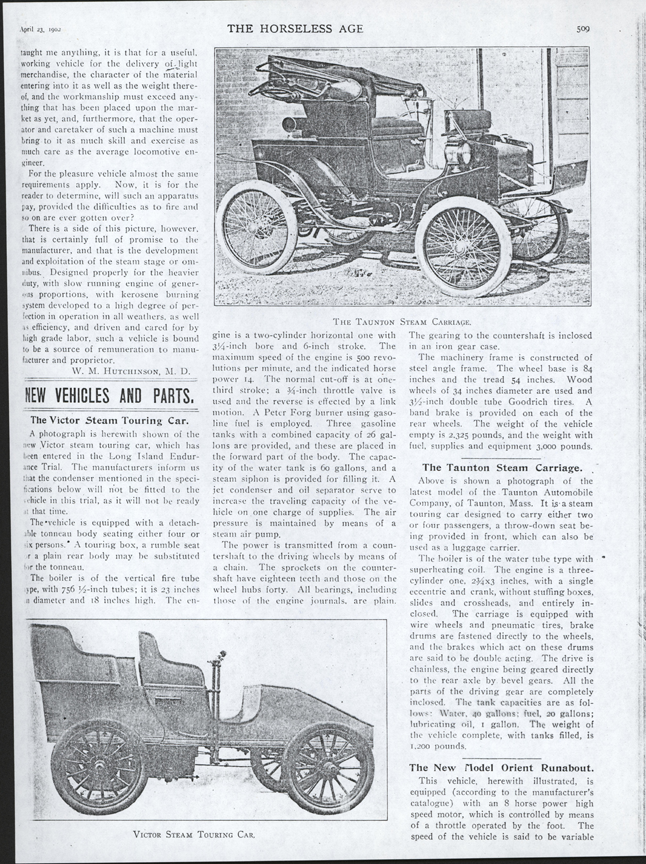

TThe Victor Steam Touring Car was featured in the April 1902 issue of Horseless Age on page 509. It shared space with the Taunton Steam Carriage. Photocopy. John A. Conde Collection.

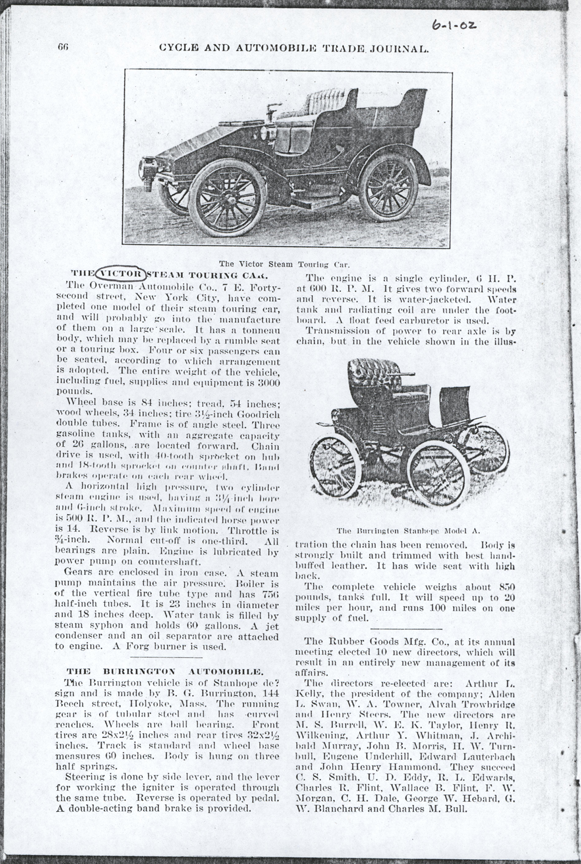

The Victor Steam Touring Car was featured in the June 1902 issue of Cycle and Automobile Trade Journal on page 66. Photocopy. John A. Conde Collection.

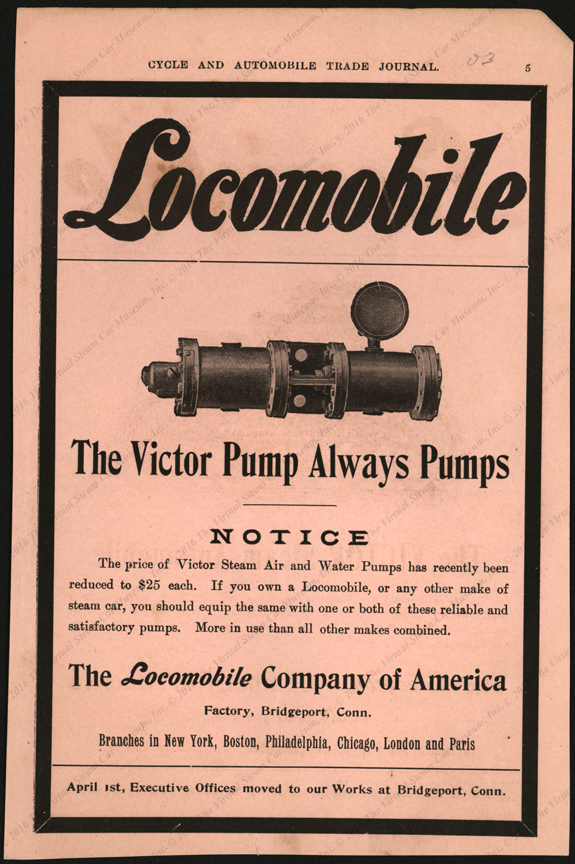

The Locomobile Company of America placed this 1903 advertisement in Cycle and Automobile Trade Journal, offering the pumps for as an afermarket item for Locomobile and other steam cars.

The Locomobile Company of America placed this 1903 advertisement in Cycle and Automobile Trade Journal, offering Victor Steam Carriages for sale, having apparently purchased the remaining inventory of the Overman Automobile Company.

Conde's File Folder for the Overman Automobile Company. He notes that the Victor Automobile Company was absorbed by Locomobile. John A. Conde Collection.

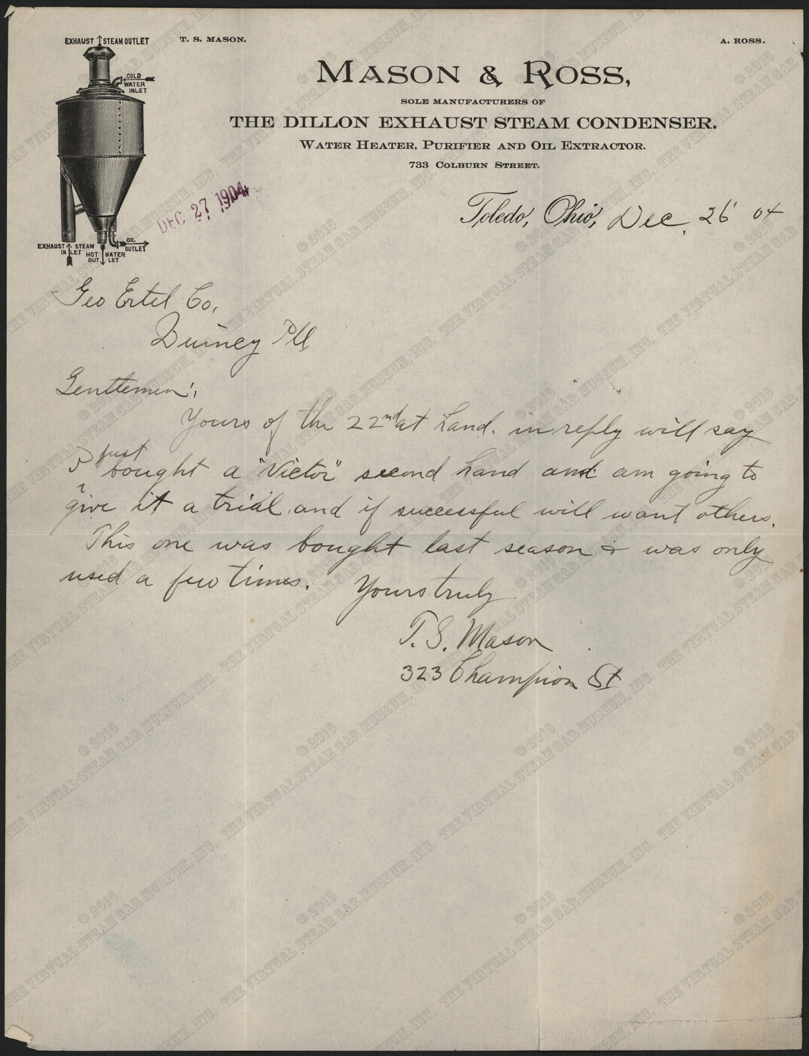

In December 1904, T. S. Mason wrote to a friend about the purchase of a "VICTOR," presumably the steam car. Mason's letterhead features a steam condenser and perhaps he envisioned using it on a steam car such as the Victor.

THE OVERMAN STEAM AUTOMOBILE[2]

The steam carriage built by the Overman Automobile Company, of Chicopee Falls, Mass. might almost be called a Franco-American vehicle, since the mechanism has the complexity of detail of the French machines, while the Yankee ingenuity of the New Englanders seen in the invention and method of assembling the parts. The carriage has been thoroughly tested during the last year; and many of the parts are now built stronger than heretofore, while the machine as a whole weighs more than last year's model.

The manufacturers of this automobile have incased its machinery as far as possible in a pressed steel body, which has the obvious advantage of being indestructible by fire. The side panels of the body below the seat can be opened, and the seat itself raised, thus allowing the machinery to be easily reached when necessary.

The principal points of interest in this carriage, which distinguish it from most other steam machines, are the automatic water feed regulator and various other similar devices, such as steam, water and air pumps, fusible plugs for putting out the fire in case of low water in the boiler, etc.

The water feed of the boiler is controlled by a thermostat, the construction and operation of which is shown. A U-shaped brass pipe, B, is connected at the upper end to the steam space of the boiler and at the lower end to the water space, so that the upper half is normally filled with steam and the lower half with water. This water is kept cool by a jacket, 0, through which the feed water from the tank is pumped before going to the feed-water heater. On each side of the upper part of B are guide plates, A, in the ends of which the rod, R, is mounted. This rod runs forward along the side of the carriage and carries a finger, F, adapted to raise or lower the by-pass valve, P. D is a tongue soldered to the tube, B, at its upper bend and acting on R through the arm, E. When the water level rises in the boiler, the cool water enters the upper part of B and causes it to contract. This contraction is sufficient, when multiplied a few times by the lever arrangements, to open the bypass valve, P, and allow the water to be pumped back into the tank. In like manner, when the level falls, the bypass valve is closed.

The pump used to supply the boiler differs from those usually employed in that it is of the double-acting, slow-running type, and is driven by the back axle instead of by the engine. A small gear on the axle drives a larger gear that carries a crank pin. Fastened to the crank pin is one end of a long rod, the other end of which is attached to the pump. By the rotation of the gear carrying the crank pin, the rod and pump are given the necessary reciprocal movement. The water is heated before entering the boiler by passing through a 48-foot coil of copper tubing inclosed [sic] in a shell through which the engine exhausts.

An injector is conveniently placed for filling the water tank when on the road. With the tank full of water, valves may be opened, and the water allowed to run into the boiler to the proper level, should the latter be empty and without steam. This is a very convenient way of getting water into the boiler.

The steam water and air pumps are started by turning a small lever beside the seat either forward or backward. The lever is on the end of a rod that runs across under the seat and carries a small eccentric at a point near the pumps. The eccentric raises or lowers a rac.ker arm, that serves to open the valve to either the air or water pump. Besides being thus under the control of the operator, the air pump is also furnished with a pressure diaphragm regulator which starts and stops it automatically should' the pressure in the fuel tank fall four pounds.

The boiler and burner are of the usual type. The latter is started by burning some wood alcohol in a trough that runs across it beneath the main vaporizing tube. The alcohol is introduced through a funnel situated inside the panel below the driver's seat. The gasoline, before passing through the vaporizing tube, circles around the in¬side of the burner through a coil of pipe, where it is initially heated.

The burner flame is controlled by the usual pressure diaphragm, but there is also a flame accelerator that can be operated from the seat and by which the flame can be increased if more heat is needed, as in climbing a bad hill. The boiler is provided with a superheating coil, which is situated in the combustion chamber directly over the flame.

Should the water run low in the boiler, the steam will melt a fusible plug and close a valve, thus shutting off the gasoline and extinguishing the fire. This will happen while there is still two inches of water in the boiler, so that the chances are very slight of the machine ever being laid up from a burned-out boiler.

The boiler has two water glasses also (one inside and one outside of the body), so that the water level can always be ascertained. Should either of the glasses get broken, back check valves immediately close and shut off the water and steam. A third glass indicates the water level in the tank.

The engine of the Overman carriage is of the piston valve type, and has the cranks completely inclosed [sic] and running in oil. Plain bearings are used throughout. The cylinders are 2-inch bore by 3-inch stroke. The engine is mounted on hollow trunnions, which form admission and exhaust pipes respectively, and its lower end can be swung forward for tightening the chain. The exhaust from the engine is run into the tubing of the frame, whence it issues into the atmosphere through a series of small holes.

An auxiliary third gage shows the amount of gasoline in the tank. At night, by pressing a button, all three gages can be illuminated by a small electric light, and although the presence of the automatic feed water regulator renders inspection of the water glass unnecessary, this too can be instantly illuminated by pressing another button. It will thus be seen that this carriage is complete even to the minutest detail, and has' all possible devices that are known at present for the comfort and convenience of the operator.